YORKLYN FAKE NEWS

Fake News, also referred to as yellow journalism in the past, is the publishing or sharing of misleading information, presented in a news format, with the purpose of causing damage or harm to a business, person, government, or similar. According to scholars, the last time levels of fake news usage reached epidemic levels similar to what we experience today was in the 1890s. In 1894 Frederick Burr Opper penned a cartoon highlighting reporters anxious to spread fake news to their readership.

Fake News, also referred to as yellow journalism in the past, is the publishing or sharing of misleading information, presented in a news format, with the purpose of causing damage or harm to a business, person, government, or similar. According to scholars, the last time levels of fake news usage reached epidemic levels similar to what we experience today was in the 1890s. In 1894 Frederick Burr Opper penned a cartoon highlighting reporters anxious to spread fake news to their readership.

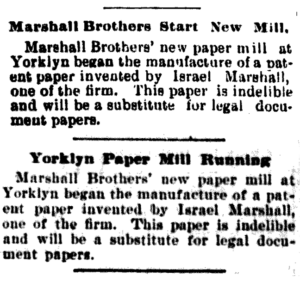

Displayed are two articles found in the Evening Journal and one in The Sun in 1900 and 1901. All three articles involve Israel Marshall and are obviously fake news reporting. The Marshall family were of Quaker belief making a reference to becoming a large manufacturer of a tobacco product dubious. While not banned, alcohol and tobacco products were generally avoided by the Marshalls.

Displayed are two articles found in the Evening Journal and one in The Sun in 1900 and 1901. All three articles involve Israel Marshall and are obviously fake news reporting. The Marshall family were of Quaker belief making a reference to becoming a large manufacturer of a tobacco product dubious. While not banned, alcohol and tobacco products were generally avoided by the Marshalls.

The Marshall’s expertise was in making industrial rag paper and their three paper mills were operating near maximum capacity. If anything, they might have considered a fourth papermaking plant and not competing with their neighbor, the Garrett family, who produced 1.5 million pounds of smokeless tobacco products annually by 1900.

While ink can be indelible, papers generally were not a century ago. In the late 1800s, ‘indelible pencils’, also known as ‘copying pencils’, were the means used for copying documents. An individual composed a document using an indelible pencil containing a water-soluble dye mixed with the graphite. When the document was complete, a piece of moist tissue paper, placed on the document and pressed with a warm iron, transferred the dye from the graphite writing to the tissue paper providing a copy that could be read through the tissue paper when placed against a window pane.

Why might these fake news articles have appeared in local newspapers?

Answer

The ‘new mill’ referenced is no doubt the Insulite Mill that was constructed in 1899-1900 diagonally across from the Marshall Brothers Mill on Benge Road. While what follows is speculative, it is based on known facts of the time.

The ‘new mill’ referenced is no doubt the Insulite Mill that was constructed in 1899-1900 diagonally across from the Marshall Brothers Mill on Benge Road. While what follows is speculative, it is based on known facts of the time.

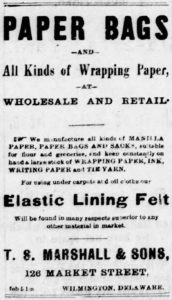

Israel and Elwood Marshall supplied the vulcanized fibre manufacturing market industrial rag paper for several decades prior to 1900. The Marshall companies of T.S. Marshall & Son (Marshalls Bridge, PA), Marshall Brothers (Yorklyn, DE), and Marshall & Mitchell (Wooddale, DE) were premier suppliers of vulcanizing paper to more than a half dozen firms in Wilmington, Newport, Stanton, and Newark.

Israel would have visited vulcanized fibre organizations numerous times to understood how each made their vulcanized fibre when he was called upon to develop a custom paper for a particular firm. Records reference Marshall papers returned for failure to vulcanizing properly which Israel might have investigated with a trip to the vulcanized fibre company. This access provided Israel a unique perspective and insight into the best (and not so good) ways of converting Marshall rag paper into fibre using zinc chloride as well as the many problems that plagued the labor-intensive manufacturing processes.

From Israel’s fibre company visits we can logically deduce that by the late 1890s Israel would have started to develop concepts relating to an automated vulcanized fibre manufacturing process using Marshall cotton rag paper as the primary raw material. The issue for Israel would have been how to physically prototype his automated fiber-making process without alerting his paper customers that he was doing so! Fortunately for Israel there were several means to do this at his disposal.

In 1898 Israel and Elwood had started the Fibre Specialty Company in Kennett Square to make the Hercules line of vulcanized fibre cases, trunks, suitcases, and similar products. Marshall rag paper went to one of the vulcanized fibre companies for conversion into fiber sheet which Fibre Specialty then purchased for the construction of their manufactured products. There are general ledger entries indicating Marshall Brothers specialty papers went directly to Fibre Specialty for conversion into finished products.

Israel’s 1887 patent for the ‘Manufacture of Water-Proof Building-Paper’ (Patent 356,367) which may have been made at the Homestead Mill during the 1880s. This patent describes a replacement product for tar paper that was saturated with resin, tallow, lard, or similar. Sold through the Marshall paper store in Wilmington under the name of Pioneer Building Paper, it was advertised for its lack of odor unlike the coal-tar based papers it competed with. The Marshalls also advertised their paper for carpet underlayment among other uses as the included ads from the period indicate. The patent describes a manufacturing process very much mimicking vulcanized fibre production.

To manufacture finished goods such as cases and trunks and create specialty paper products, a supplier of manufacturing equipment must have been required. Wilmington Malleable Iron Company manufactured presses, punches, and steam bending machines suitable for working vulcanized fibre and other materials. While we don’t know if Israel and Elwood purchased machinery from William H. Bayley, president to Wilmington Malleable Iron Company, the possibility seems likely. Note that the reference to T.S. Marshall (Thomas Smedley Marshall – Israel & Elwood’s father) was probably T.E. Marshall (Thomas Elwood Marshall, Israel’s younger brother) as T.S Marshall had passed away in 1887.

To manufacture finished goods such as cases and trunks and create specialty paper products, a supplier of manufacturing equipment must have been required. Wilmington Malleable Iron Company manufactured presses, punches, and steam bending machines suitable for working vulcanized fibre and other materials. While we don’t know if Israel and Elwood purchased machinery from William H. Bayley, president to Wilmington Malleable Iron Company, the possibility seems likely. Note that the reference to T.S. Marshall (Thomas Smedley Marshall – Israel & Elwood’s father) was probably T.E. Marshall (Thomas Elwood Marshall, Israel’s younger brother) as T.S Marshall had passed away in 1887.

In addition, American Tobacco Company, recent new owner of the Garrett Snuff Mills, was erecting another snuff mill adjacent to the former Garrett Snuff Mill #2. Constructed to replace the Garrett’s Philadelphia store where smokeless tobacco products were manually packed, the new mill utilized modern automated packing equipment. While the actual Garrett equipment supplier is unknown, packing equipment was another product produced by the Wilmington Malleable Iron Company. The newspaper article relating to erecting a large snuff mill definitely qualifies as fake news either by honest error on the part of the writer or on the part of those providing the information so as not to tip off competitors as to actual plans.

The Marshalls may have wished to expand the production of Pioneer Building Paper which was first made at their Homestead Paper Mill at Marshalls Bridge, PA. The Insulite Mill construction was started in 1899 and completed in 1900. On the first floor, Pusey & Jones equipment used by some of the local vulcanized fibre companies, was installed. While it is difficult to know for sure, it is entirely possible for Pioneer Building Paper to have been manufactured on the ground floor of the new Yorklyn mill using fiber-making equipment.

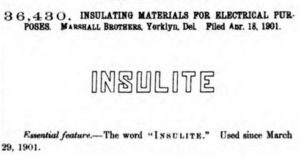

It is interesting to note that in 1901 the Marshall’s received a trademark for ‘Insulite’, a paper for electrical insulating use. We know from Marshall Brothers general ledger entries that Israel produced cotton rag papers containing asbestos, mica, and other minerals mixed with the pulp at Yorklyn! The asbestos and mica impregnated rag papers, made in the Marshall Brothers Mill, while not suitable for vulcanizing, might have been treated in the Insulite Mill with similar coating materials used in making Pioneer Building Paper. Various resins and lacquers found use in the electrical industry a century ago to bind materials together, especially electrical insulating materials. The Marshalls sold their Insulite paper for 20-cents per pound. The manufacture of ‘Insulite’ at Yorklyn might explain the newspaper articles describing indelible papers in that the reporter confused ‘insulite’ with ‘indelible’.

It is interesting to note that in 1901 the Marshall’s received a trademark for ‘Insulite’, a paper for electrical insulating use. We know from Marshall Brothers general ledger entries that Israel produced cotton rag papers containing asbestos, mica, and other minerals mixed with the pulp at Yorklyn! The asbestos and mica impregnated rag papers, made in the Marshall Brothers Mill, while not suitable for vulcanizing, might have been treated in the Insulite Mill with similar coating materials used in making Pioneer Building Paper. Various resins and lacquers found use in the electrical industry a century ago to bind materials together, especially electrical insulating materials. The Marshalls sold their Insulite paper for 20-cents per pound. The manufacture of ‘Insulite’ at Yorklyn might explain the newspaper articles describing indelible papers in that the reporter confused ‘insulite’ with ‘indelible’.

On the second floor of the Insulite Mill, Israel prototyped his eventually patented Endless Fibre Machine. While the first floor might have been making Insulite paper or even vulcanized fibre using equipment and processes in common use at the time, on the second floor, Israel and a couple of trusted employees, worked undisturbed on development of the endless fibre machine! We know that at the end of 1904 the Marshalls incorporated National Fibre & Insulation and began construction of the #1 Fibre Mill. Tom Marshall has written that equipment from the Insulite Mill was relocated to the #1 Fibre Mill after the building was reconstructed a second time in 1905 as a result of a tornado destroying the still under construction mill building (shown above from the Clarence Marshall Collection at Hagley Digital Archive).

On the second floor of the Insulite Mill, Israel prototyped his eventually patented Endless Fibre Machine. While the first floor might have been making Insulite paper or even vulcanized fibre using equipment and processes in common use at the time, on the second floor, Israel and a couple of trusted employees, worked undisturbed on development of the endless fibre machine! We know that at the end of 1904 the Marshalls incorporated National Fibre & Insulation and began construction of the #1 Fibre Mill. Tom Marshall has written that equipment from the Insulite Mill was relocated to the #1 Fibre Mill after the building was reconstructed a second time in 1905 as a result of a tornado destroying the still under construction mill building (shown above from the Clarence Marshall Collection at Hagley Digital Archive).