BOGEY

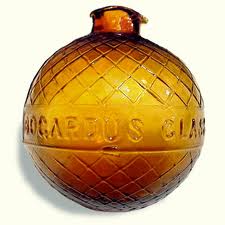

Trap shooting is the oldest shotgun sport in America having evolved from the shooting of live pigeons in England during the late 1700s. By the middle 1800s, pigeon shooting clubs had sprung up across America and the capture of live pigeons could not keep up with demand. Various alternates for the live birds were tried including glass balls filled with pigeon feathers as is on display in Auburn Heights mansion. In 1880 George Ligowsky of Cincinnati, OH invented the clay target, known as the “clay pigeon.” The first U.S. National Championship was held in New Orleans, LA, in 1885. In 1921 T. Clarence Marshall established the Yorklyn Gun Club, which lasted until 1950.

Trap shooting is the oldest shotgun sport in America having evolved from the shooting of live pigeons in England during the late 1700s. By the middle 1800s, pigeon shooting clubs had sprung up across America and the capture of live pigeons could not keep up with demand. Various alternates for the live birds were tried including glass balls filled with pigeon feathers as is on display in Auburn Heights mansion. In 1880 George Ligowsky of Cincinnati, OH invented the clay target, known as the “clay pigeon.” The first U.S. National Championship was held in New Orleans, LA, in 1885. In 1921 T. Clarence Marshall established the Yorklyn Gun Club, which lasted until 1950.

Pigeons were caught in wooden boxes called “traps” and is from which the name for the sport originates. While “trappers” were the individuals that caught the live pigeons, the term was carried over to the sport to become the name given the individual that released Ligowsky’s clay pigeons into the air. The spring-loaded device that originally flung a clay pigeon into the air would be cocked and loaded by the trapper. A strong tug on a cord by the trapper released the clay pigeon into the air and is the basis for the term “pull” said by a shooter when he’s ready for a clay pigeon to be released.

In trap shooting a clay pigeon is released into a flightpath somewhat parallel to the shotgun’s barrel whereas with skeet shooting the target is released to fly perpendicular to the shotgun’s barrel. The term “bogey” refers to a clay pigeon that is released at an extreme angle (up to 22.5-degrees) to the line between the shooter and trap house.

In trap shooting a clay pigeon is released into a flightpath somewhat parallel to the shotgun’s barrel whereas with skeet shooting the target is released to fly perpendicular to the shotgun’s barrel. The term “bogey” refers to a clay pigeon that is released at an extreme angle (up to 22.5-degrees) to the line between the shooter and trap house.Answer

Another use of the term “bogey” is a defined standard of performance to be met. The term was often encountered when purchasing audions, also known as vacuum or electron tubes at the start of the 1900s. On display in the Marshall Steam Museum is a very early Westinghouse shortwave radio. Inside the radio are three electron tubes. The three tubes as well as the other electronic components had optimum or bogey values defined which insured the optimum performance of the radio.

Another use of the term “bogey” is a defined standard of performance to be met. The term was often encountered when purchasing audions, also known as vacuum or electron tubes at the start of the 1900s. On display in the Marshall Steam Museum is a very early Westinghouse shortwave radio. Inside the radio are three electron tubes. The three tubes as well as the other electronic components had optimum or bogey values defined which insured the optimum performance of the radio.

The vacuum tubes in the radio had limited life (generally only a couple years). As radio performance degraded, Clarence would have to replace the vacuum tubes. While numerous companies such as RCA, Philips, and Western Electric made replacement tubes, spending more money for “bogey tubes” ensured optimum performance for the radio. Bogey tubes are those tubes were all required critical specifications were within the specified tolerance for the given performance value.

The two large power tubes in the image below normally should not display a blue glow. The only color should be the orange of the heated filaments similar to the smaller tubes at left. The blue glow is plasma discharge occurring with air molecules inside the glass envelope indicating the tube is becoming “gassy” by losing its vacuum. The tube’s performance will degrade as additional leakage occurs until failure. The orange glow produced by the incandescent filament is similar to a light bulb’s operation and the filament eventually burns up as more oxygen enters the glass envelope.

In the early days of electronics manufacturing, seven levels quality control were sometimes used to define how a manufactured component could be used. The highest quality level, a bogey component such as a bogey tube, was assigned quality control levels 1 through 4. These would be sold as the premium, highest quality components and commanded the highest prices. Level 1 tubes, with performance levels exactly meeting specification with little variance, would be destined for internal company use as well as military products. Level 2 components would go into company products with level 3 units sold to other companies for use in their products. Level 4, was just within specification, were often sold as retail product in America and to foreign companies. Level 5 and 6 would have one or more quality control parameters out of specification but still perform reasonably well. These off-specification units would be sold to foreign markets for use by equipment makers and experimenters and hobbyists. Level 7 had most specification parameters out of range and end up being sold to recyclers.