AN OUNCE OF PREVENTION

Anyone who has toured Marshall Brothers paper mill (two tours left in 2023 – October 28th & November 18th), is aware of the variety of dangerous machinery installed in the 1890s mill which made paper into the 21st century. Additionally, as papermaking is a water-based process, wet, uneven, concrete flooring provided ample opportunity for slippery conditions. Machines with flailing knives, rotary cylindrical boilers operating at 25 pounds per square inch steam pressure (267 degrees Fahrenheit temperatures) and large moving belts and gears added to the opportunities for worker injury.

In 1890, when the former Auburn Factory was converted to a paper mill by Israel and Elwood Marshall, only 9 states required some level of factory safety inspection. Delaware did not require boiler inspections until 1919. DuPont, the state’s biggest employer for much of the 20th century, began its safety program in 1811 and by 1927 had an injury rate of 3.4 major injuries per million hours worked. This record, and compatible records of other large Delaware employers, eliminated the need for Delaware employers to have to comply with state safety regulations. Delaware businesses had a free hand in defining workplace safety requirements until OSHA was enacted.

Congress enacted the Williams-Steiger Occupational Safety and Health Act on April 28, 1971 after President Nixon’s December 1970s signing. The Occupational Safety and Health Administration (OSHA) was created by the Act to ensure America’s work practices and environments were safe for all employees, contractors, and visitors, Not only was OSHA tasked with defining a safe workplace through regulations and policy, the organization had the power to levy fines where failure to comply could be documented either through unannounced inspection or investigation after a reportable injury occurred.

Congress enacted the Williams-Steiger Occupational Safety and Health Act on April 28, 1971 after President Nixon’s December 1970s signing. The Occupational Safety and Health Administration (OSHA) was created by the Act to ensure America’s work practices and environments were safe for all employees, contractors, and visitors, Not only was OSHA tasked with defining a safe workplace through regulations and policy, the organization had the power to levy fines where failure to comply could be documented either through unannounced inspection or investigation after a reportable injury occurred.

Recently the NVF corporate records have been parsed for the company’s safety performance. We know, for example, in 1982 NVF Yorklyn recorded 27 safety incidents for 348,855 hours worked for fiber operations and recorded 11 safety incidents for 153,671 hours worked for papermaking operations. The research indicates these numbers were not uncommon, in fact 1982’s data was statistically average for injury data reported to OSHA during the 1980s and into the 1990s at NVF Yorklyn.

The data show multiple examples of lacerations, bruises, strains, and sprains. Think back to how you have injured yourself when a slipping knife has not been the cause of a laceration, tripping over an object has not resulted in a fall, to the more unique accidents that have caused you injury. How many of those unique accidents do you think may not have been unique, but occurred at NVF Yorklyn? For our Answer we will describe some of the recordable accidents at NVF Yorklyn

Answer

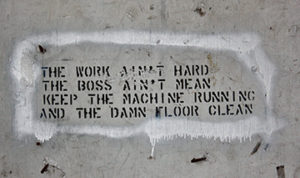

As one reads through decades of recordable safety incidents occurring on an annual basis at Yorklyn, not using proper safety equipment such as eyewear, gloves, footwear, and even simple clothing were frequently cited as contributing to dozens of annual injuries. While failure to use safety equipment contributed to many injuries, working conditions and employee willingness to follow safety guidelines accounted for quite a few injuries. Perhaps most noteworthy were the uneven walking surfaces throughout the facilities creating numerous opportunities for trips, falls, and sprains Improper lifting and moving often resulted in back and groin injuries. Properly maintaining equipment was often cited when handrails or other safety devices failed to perform as intended due to not having been tested or maintained.

Employees using hammers had the hammer ricochet off what was being struck and strike the employee at various locations. There are numerous examples of employees working with either the paper sheet or the fibre sheet and getting their fingers and arms caught between the rollers or other machine parts. Employees were injured using thread-up tooling they concocted for various uses around machinery or the employee became injured pulling and cutting paper/fiber from a machine where the material had tightly wrapped within the machinery. There are incident reports documenting removed guard(s) and had the guard(s) been in use, the incident would not have happened or the injury might have been significantly less.

There was one death recorded at NVF Yorklyn when an employee operating a fork truck at high speed (with a failed braking system) swerved to miss other employees and crashed into a building support column bringing part of an upper floor down upon the fork truck that did not have a safety cage for the operator. In another incident an employee lost 143 workdays while mowing grass with a tractor after they collided with a 55-gallon steel drum that was visible for some distance. The employee was thrown from the tractor and had the old-fashioned reel mower being towed behind the tractor run over them resulting in broken legs and pelvis, lacerations, and serious internal injuries.