BEFORE THERE WERE PACKARDS

Answer

The Packard Electric Company was formed on June 5, 1890, around the same time as Israel and Elwood Marshall purchased the burned-out woolen mill at Yorklyn. The Packard Electric Company advertised electric bells, burglar alarms, gas lighting, and arc and incandescent electrical lighting plants during the late 1800s, and the Packard Electric name lasted into the mid-1920s. The Packard brothers owned the New York and Ohio Company, which manufactured Packard electric lamps. The plant eventually became the Packard Lamp Division of General Electric.

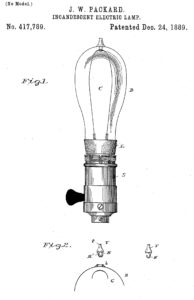

Of the two Packard brothers, James Ward Packard was the inventor while his brother, William Doud Packard, preferred to concentrate on running their several electrical businesses. Thirteen of the 43 patents the brothers obtained were devoted to electric lamp manufacturing operations. The patents included electric lamp construction techniques and manufacturing equipment, including mercury vacuum pumps, electric lamp sockets, and fuse-wire holders for circuit fusing.

Of the two Packard brothers, James Ward Packard was the inventor while his brother, William Doud Packard, preferred to concentrate on running their several electrical businesses. Thirteen of the 43 patents the brothers obtained were devoted to electric lamp manufacturing operations. The patents included electric lamp construction techniques and manufacturing equipment, including mercury vacuum pumps, electric lamp sockets, and fuse-wire holders for circuit fusing.

The earliest Packard patents are dated in the late 1880s, with later Packard lamp patents assigned to the Westinghouse Electric Company. One of the difficulties that competitors to Edison encountered was developing a lamp that didn’t infringe on the original Edison patent. Competitors looked for manufacturing process advantages as well as design feature differences to avoid infringement on Edison patents. James Packard’s various patents addressed both the design and manufacturing processes of lamp manufacture.

Packard electric lamps became very well known and widely used, and the Packard lamp design, manufactured though Westinghouse, was a major competitor to Edison’s electric lamp business. The Packards worked with George Westinghouse, who promoted Tesla’s polyphase alternating current (AC) power system against the Edison/General Electric direct current (DC) power system. Without the ability to offer an electric lamp that did not infringe on Edison’s patents, Westinghouse and Tesla would not have been able to compete.

Packard electric lamps became very well known and widely used, and the Packard lamp design, manufactured though Westinghouse, was a major competitor to Edison’s electric lamp business. The Packards worked with George Westinghouse, who promoted Tesla’s polyphase alternating current (AC) power system against the Edison/General Electric direct current (DC) power system. Without the ability to offer an electric lamp that did not infringe on Edison’s patents, Westinghouse and Tesla would not have been able to compete.

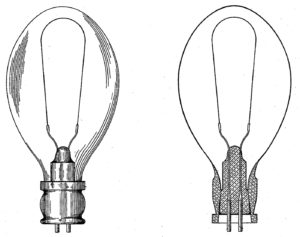

Westinghouse’s use of “stopper in a bottle” lamp construction got around the Edison patent, which allowed inventors such as James Packard to add features producing lamps superior to what Edison offered through General Electric. One of Packard’s patents added an intermediate support means for long fragile carbon filaments inside a lamp thus limiting a long filament’s tendency to vibrate and break from mechanical flexing fatigue. The addition of Packard’s filament support greatly increased lamp life for railroad, trolley, and automotive applications that subjected lamps to constant vibration. The glass enclosures were frosted to more evenly disperse the filament’s incandescence and made with ribs for decoration as well as to add strength to the glass.

The 1892 World Columbian Exposition in Chicago was lit using Westinghouse AC power system, which employed more than 200,000 Westinghouse-built Sawyer-Man stopper electric lamps in the lighting fixtures. The success of the Westinghouse demonstration at the Exposition is considered a watershed event that proved Tesla’s polyphase AC power distribution systems were in fact superior to the Edison-General Electric DC power distribution system. The Packard Electric lamp patents used by Westinghouse for the display, including on carousels and other rides, demonstrated superior life expectancies against competitor’s lamps further proving Westinghouse and Packard Electric produced superior lamps to Edison/GE.

The 1892 World Columbian Exposition in Chicago was lit using Westinghouse AC power system, which employed more than 200,000 Westinghouse-built Sawyer-Man stopper electric lamps in the lighting fixtures. The success of the Westinghouse demonstration at the Exposition is considered a watershed event that proved Tesla’s polyphase AC power distribution systems were in fact superior to the Edison-General Electric DC power distribution system. The Packard Electric lamp patents used by Westinghouse for the display, including on carousels and other rides, demonstrated superior life expectancies against competitor’s lamps further proving Westinghouse and Packard Electric produced superior lamps to Edison/GE.

Lamps of the 1890s only had a few hundred hours operating time, and often the electric used during a lamp’s short lifetime was more costly than the lamp’s purchase. The brighter the bulb the shorter it’s lifetime generally. As Westinghouse lamps were of the “stopper” design, the company’s rebate program returned burned-out lamps to the factory. Stoppers were removed from the glass envelope, the filament replaced, and the stopper returned to the bulb envelope once the envelope had been cleaned inside. This greatly reduced the cost of a Westinghouse lamp to that of an Edison-GE lamp.

Lamps of the 1890s only had a few hundred hours operating time, and often the electric used during a lamp’s short lifetime was more costly than the lamp’s purchase. The brighter the bulb the shorter it’s lifetime generally. As Westinghouse lamps were of the “stopper” design, the company’s rebate program returned burned-out lamps to the factory. Stoppers were removed from the glass envelope, the filament replaced, and the stopper returned to the bulb envelope once the envelope had been cleaned inside. This greatly reduced the cost of a Westinghouse lamp to that of an Edison-GE lamp.

Packard electric lamps were easily identified by the paper tag that was placed in the cement which held the base to the glass. The script “Packard” as their logo along with the bulb’s candlepower and operating voltage were printed on the tag.

Packard electric lamps were easily identified by the paper tag that was placed in the cement which held the base to the glass. The script “Packard” as their logo along with the bulb’s candlepower and operating voltage were printed on the tag.